Discount Price X3 Vibration Plate - CNC Technology – Chengzhou

Discount Price X3 Vibration Plate - CNC Technology – Chengzhou Detail:

Chengzhou Processing Service Capability

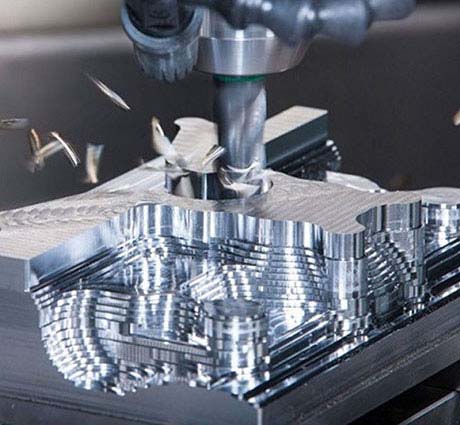

As one of CNC factory in China, the following machining capabilities in Chengzhou are available to serve your CNC machined parts needs, from rapid prototyping to precision parts and tooling to end-use production.

● CNC Steering

● CNC Milling

● CNC Drilling

● CNC Milling and Steering

● Wire EDM

Chengzhou CNC machining materials

Chengzhou, CNC services use a lot of metals, plastics and other types of materials.

● Aluminum: 2024, 5083, 6061, 6063, 7050, 7075, etc.

● Alloy: Brass 360, 101 Copper, 110 Copper, 932 Copper, Zinc, etc.

● Titanium: Grade 2, Grade 5, etc.

● Stainless steel: 303, 304, 410, 17-4, 2205 duplex, 440℃, 420, 316, 904L, etc.

● Steel: 4140, 4130, A36, 1018, etc.

● Plastics: POM (Delrin), ABS (Acrylonitrile Butadiene Styrene), HDPE, Nylon, PLA, PC (Polycarbonate), PEEK (Polyetheretherketone), PMMA (Polymethylmethacrylate or Acrylate) ), PP (polypropylene), PTFE (polytetrafluoroethylene), etc.

● Other CNC Machining Materials: Graphite, VeroClear.

CNC CNC machining surface treatment

You can choose from a wide variety of metal finishing services to improve part appearance, surface smoothness, corrosion resistance and other properties of corroded parts after machining at Chengzhou CNC machining manufacturer.

● Painting

● Passivation

● Electroplating/Electroplating

● Powder Coating/Powder Coating

● Anodizing/anodizing

● Polishing

● Black Oxide

● Conversion Coating

● Bead blasting/bead blasting

● Abrasive blasting/sandblasting

Our CNC Equipment

Chengzhou has various types of high-end CNC precision machining equipment imported from abroad, including lathes, precision milling machines, wire cutting machines, precision grinders, tapping machines, drilling machines, CNC computer gongs, etc. Can undertake most precision machinery automation equipment manufacturing, mechanical parts, hardware, manufacturing.

Cutter type CNC lathe

Turret locomotive milling compound series

Single-spindle turning and milling

Single-spindle turning and milling

Cutter type CNC lathe

Cutter type CNC lathe

Turret CNC Lathe

Single-spindle turning and milling

Single/dual spindle turning and milling compound series

Double spindle CNC lathe (Y axis)

Single/dual spindle turning and milling

Double spindle CNC lathe series

Product detail pictures:

Related Product Guide:

We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for Discount Price X3 Vibration Plate - CNC Technology – Chengzhou , The product will supply to all over the world, such as: Angola, Zimbabwe, Turkey, Besides there are also experienced production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable solutions quality, increase customers' satisfaction and achieve win-win situation .

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.