Factory Cheap Hot Vacuum Gripper Robot - CR Collaborative Robot Series – Chengzhou

Factory Cheap Hot Vacuum Gripper Robot - CR Collaborative Robot Series – Chengzhou Detail:

CR Collaborative

Robot Series

The safest flexible cobots

in the world for industrial usage

ABOUT CR COBOT SERIES

Empowered by a wide range of payload from 3 to 16kg, our cobots are applicable to multiple industries. They operate in a 6-axis mode, enabling the high level of their flexibility.

EASY TO DEPLOY

QUICK TO PERFORM

Improve the flexibility of your product line and production efficiency by using an easy to deploy CR collaborative robot within 20 minutes to set up and quickly put into application within 1 hour to perform.

ACCESSIBLE

EASY TO MASTER

Our software and arithmetic technology makes the operation and management of the CR collaborative robot series intelligent and straightforward. It can accurately emulate human actions by demonstrating the path. No programming skills are required for that.

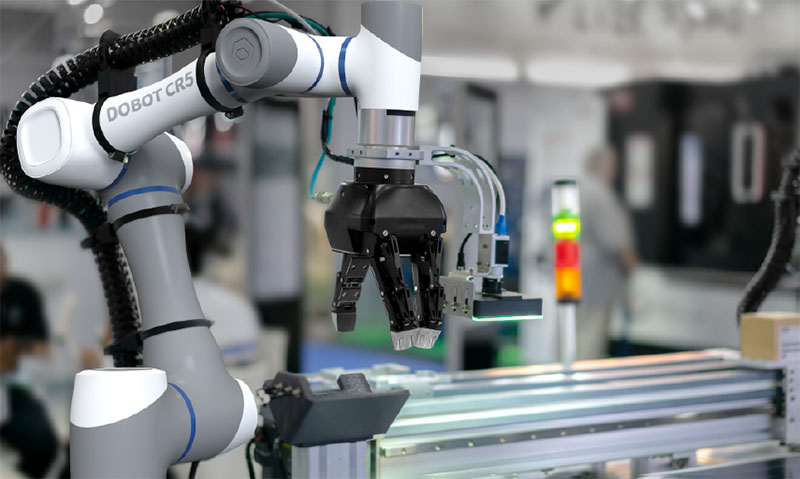

EXPANDABLE

COMPATIBLE

CR collaborative robot series is recommended not only because of its extensive portfolio of end of arm tooling devices but also because of universal communication interfaces. Featuring multiple I/O and communication interfaces makes CR collaborative robot series widely expandable and compatible with many end of arm tooling devices. As a result, CR collaborative robots satisfy a wide range of needs in various application scenarios.

INVESTMENT SECURITY

SUPER RELIABLE

CR collaborative robot series is solid and durable to ensure a long life span of 32000 hours of service life. It also has tight tolerances to ensure the investment’s security and higher ROI.

DOBOT SafeSkin (add-on)

DOBOT’s exclusive SafeSkin technology is a wearable non-contacting collision detection product for collaborative robots.

With the electromagnetic induction in SafeSkin, the CR collaborative robot series can detect an electromagnetic object quickly within 10ms and stop moving to avoid contacts or injuries until the object moves away and resume operation without compromising production automatically.

APPLICATIONS

DOBOT ECOSYSTEM

DOBOT ecosystem boosts the automation environment, consisting of a wide range of end-effectors and other accessories. From suction tools to force sensors, our robot ecosystem serves the tastes of various customer needs.

Experienced in operating in multiple applications, including loading and unloading, sorting, assembly, and others, the DOBOT ecosystem is also suitable for rich production characteristics, such as objects of different sizes, shapes, weight, and even tactile perception.

DOBOT CR collaborative robot series is expandable to a wide range of accessories to fulfill businesses’ multiple needs and applications.

FREQUENTLY ASKED QUESTIONS

1. Does it have force feedback feature?

Yes. We can install 6 axis torque sensor in joint6, and we have APIs for force application.

2. Does CR series have ISO TS 15066 directive compliance?

Yes. CR series have function safety certification (Test standard: EN ISO 13849-1 and EN ISO 13849-2).

3. About SafeSkin, does it have a vision feature or inductive sensing feature?

Inductive sensing.

4. Can we send SafeSkin to customers for installation after they have received the robots?

Yes, with guidance from FAE.

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by people and can fulfill repeatedly altering economic and social wants of Factory Cheap Hot Vacuum Gripper Robot - CR Collaborative Robot Series – Chengzhou , The product will supply to all over the world, such as: Chile, Madagascar, Bangladesh, For many years, we have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.