Factory Making Auto Screwdriver With Feeder - Smart vibratory flexible feeder – Chengzhou

Factory Making Auto Screwdriver With Feeder - Smart vibratory flexible feeder – Chengzhou Detail:

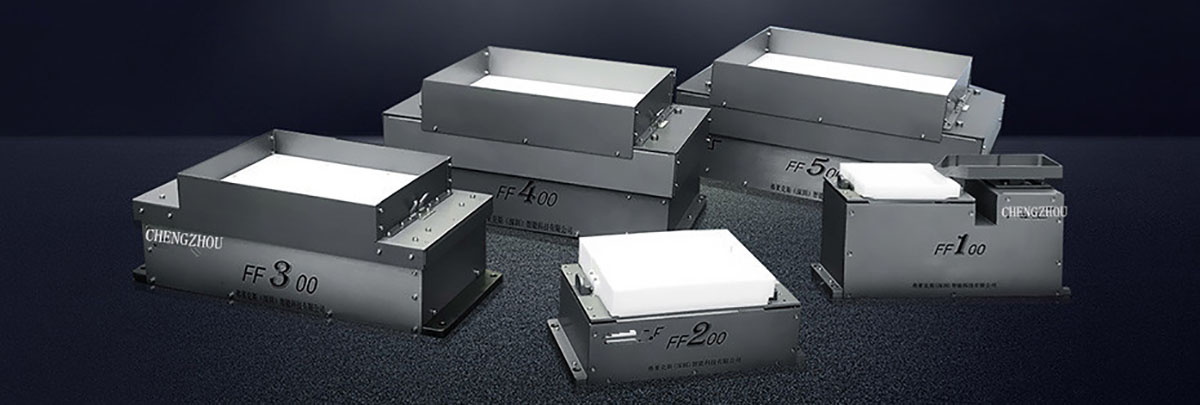

FF500

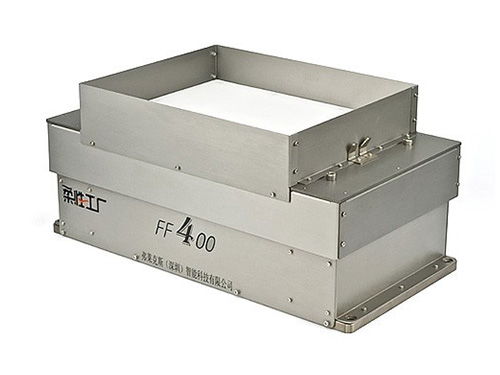

FF400

FF300

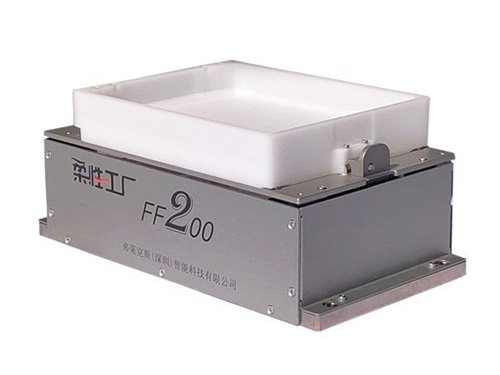

FF200

FF100

Products introduction

| Model | FF500 | FF400 | FF300 | FF200 | FF100 |

| Length * Width * Height (A*B*F) | 600*377*240 mm | 527*285*240 mm | 480*230*179 mm | 366*111*205.5 mm | 366*111*205.5 mm |

| Pickup window length * width * height (D*E*G) | 403*347*185 mm | 330*255*185 mm | 263.5*200*139 mm | 120*90*167.3*15 mm | 120*90*167.3*15 mm |

| Structural design of vibrating plate | Slot/hole/tooth/wire drawing/custom | Slot/hole/tooth/wire drawing/custom | 460*174*φ8.5 | 186*61*18 mm | 186*61*18 mm |

| Amplitude of vibration surface | G±8 mm | G±8 mm | Slot/hole/tooth/wire drawing/custom | Slot/hole/tooth/wire drawing/custom | Slot/hole/tooth/wire drawing/custom |

| Maximum displacement of vibrating plate | Length, width, height, 8-10-8 | Length, width, height, 8-10-6 | G±6mm | G±2 mm | G±2 mm |

| Pickup window load bearing | 2 KG | 1.5 KG | Length, width, height, 8-10-6 | 0.5 KG | 0.5 KG |

| Vibration plate + Plate frame (maximum weight) | 5 KG(standard plate 1.8 KG) | 4 KG(standard plate 1.3 KG) | 1 KG | 15mm | 15mm |

| Maximum allowable force applied to the platform | X-Y-Z-10-10-30N | X-Y-Z-10-10-30N | 3 KG(standard plate 1 KG) | 24 V/ 7A | 24 V/ 7A |

| Vibration suspension product height limit | 130 mm | 130 mm | 50mm | 24V/3A | 24V/3A |

| Electrical parameters (feeder) | 24 V/ 6A | 24 V/ 6A | 24 V/ 6A | White/red/green/blue | White/red/green/blue |

| Electrical parameters (backlight) | 220V(input)/24V/5A (output) | 220V(input)/24V/5A (output) | 220V(input)/24V/5A (output) | 220V(input)/24V/5A (output) | 220V(input)/24V/5A (output) |

| Backlight color option | White/red/green/blue | White/red/green/blue | White/red/green/blue | White/red/green/blue | White/red/green/blue |

| Debug software of communication mode | Standard 232 Serial port | Standard 232 Serial port | Standard 232 Serial port | Standard 232 Serial port | Standard 232 Serial port |

| External trigger mode | The passive I/O port is triggered. Procedure | The passive I/O port is triggered. Procedure | The passive I/O port is triggered. Procedure | The passive I/O port is triggered. Procedure | The passive I/O port is triggered. Procedure |

| Visual positioning system | FF SIGHT(optional) | FF SIGHT(optional) | FF SIGHT(optional) | FF SIGHT(optional) | FF SIGHT(optional) |

Advantages And Characteristics

1. Generality

Versatility Applicable to 99% of small parts and bulk materials in industrial automation production, including special-shaped parts and delicate and easily damaged parts; up to 11 motion modes, covering all vibration needs of visual feeding applications.

2. Positioning accuracy

Equipped with FF SIGHT industrial visual positioning technology, integrated backlight structure (optional), parts can be accurately positioned and grasped on the surface of the vibration plate, and the material plate can be disassembled and washed.

3. Flexible production, fast switching of production varieties

The feeding system does not need to replace the hardware structure, and the program can switch production varieties with one key, which meets the current needs of flexible production of small batches and multiple varieties of intelligent manufacturing.

4. Gentle Vibration Feeding Parts

Based on the multi-directional vibration fitting technology, the scattered parts are controlled to move in any direction on the surface of the pick-up window, the vibration amplitude and vibration mode are adjustable, the parts are fed gently, the parts do not need to be transported back and forth, the surface damage is reduced to a very low level, and there is no jamming hidden danger.

5. High reliability and long life

Based on frequency resonance fitting technology, there is no other mechanical power source and transmission mechanism, ensuring high reliability and long life.

6. Easy to integrate, easy to configure

FF series flexible feeder parameter configuration software, graphical interface, easy configuration, easy integration, can be easily integrated into various mainstream PLC and robot vision system production systems in industrial automation equipment.

7. Fast dynamic response and efficient part positioning

Based on the frequency vibration fitting technology, the vibration response time is a few ms, and the vibration dispersion can be completed as short as 100-1000 ms. Grabbed by positioning recognition.

Product detail pictures:

Related Product Guide:

We're convinced that with joint endeavours, the business between us will bring us mutual benefits. We are able to guarantee you products high quality and competitive value for Factory Making Auto Screwdriver With Feeder - Smart vibratory flexible feeder – Chengzhou , The product will supply to all over the world, such as: Mexico, Bogota, Mexico, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!