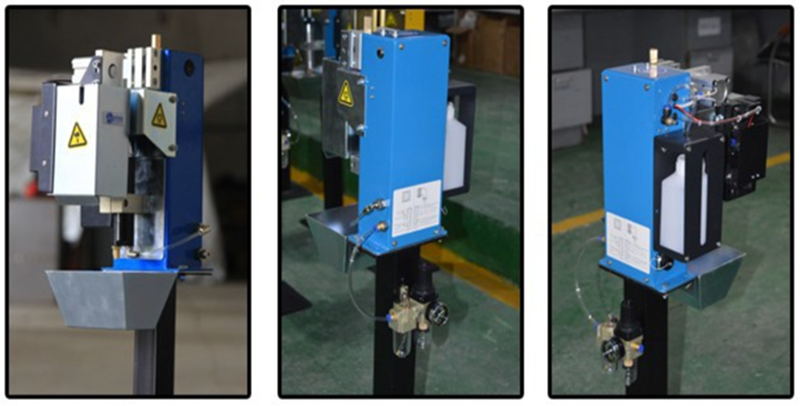

Industrial manipulator welding gun automatic cleaning device for welding torch

|

Brand |

CHENGZHOU |

|

Device model |

CZ-2000s |

|

Compressed air sourc |

Oil-free dry air 6bar |

|

The required air volume |

about 10L per second |

|

Program control |

Pneumatic |

|

Voltage |

U = 24V DC |

|

Gun clearing time |

about 4-5 seconds |

|

Anti-splash agent capacity |

500ml |

|

Anti-splash spray volume |

adjustable |

|

1. The gun cleaning and spraying design at the same position of the gun cleaning and cutting mechanism, the robot only needs-asignal to complete the gun cleaning and fuel injection actions. |

|

|

2. The whole process of cleaning the gun only takes 6-7 seconds, while other similar products require 12 seconds, which greatly saves the time for the robot to clean the gun and improves the working efficiency of the robot. |

|

|

3. Please ensure that the important components of the gun's wire-cutting mechanism are protected by a high-quality casing to avoid the impact of collision, splash and dust. |

|

|

1. Clear the gun |

|

|

It can effectively remove welding spatter attached to the nozzle for various robot welding. |

|

|

For severe "splash" paste, cleaning also has good results. |

|

|

The position of the welding nozzle during the work process is provided by the V-shaped block for precise positioning. |

|

|

2. Spray |

|

|

The device can spray fine anti-spatter liquid in the nozzle to form a protective film, which effectively reduces the adhesion of welding spatter and prolongs the use time and accessories life. |

|

|

The clean environment benefits from the sealed spray space and the remaining oil collection device |

|

|

3. Shearing |

|

|

The wire cutting device provides accurate and high-quality wire cutting work, removes the residual molten ball at the end of the welding wire, and ensures that the welding has a good starting Arc capability. |

|

|

Long service life and high degree of automation. |

|

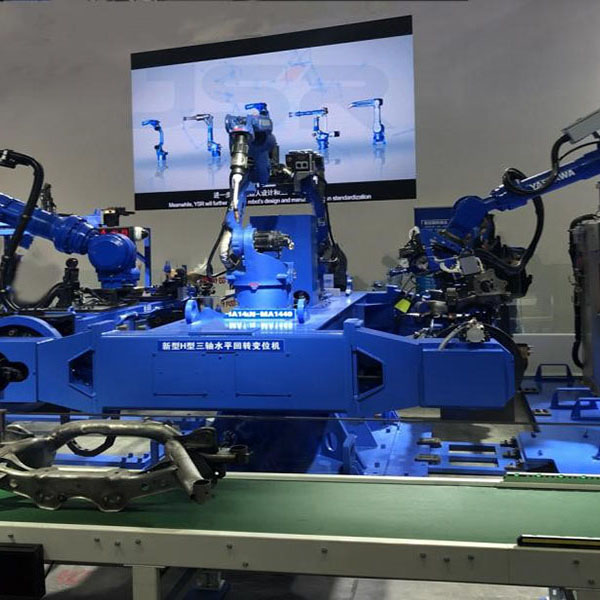

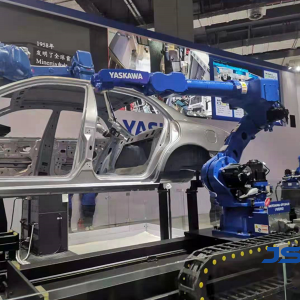

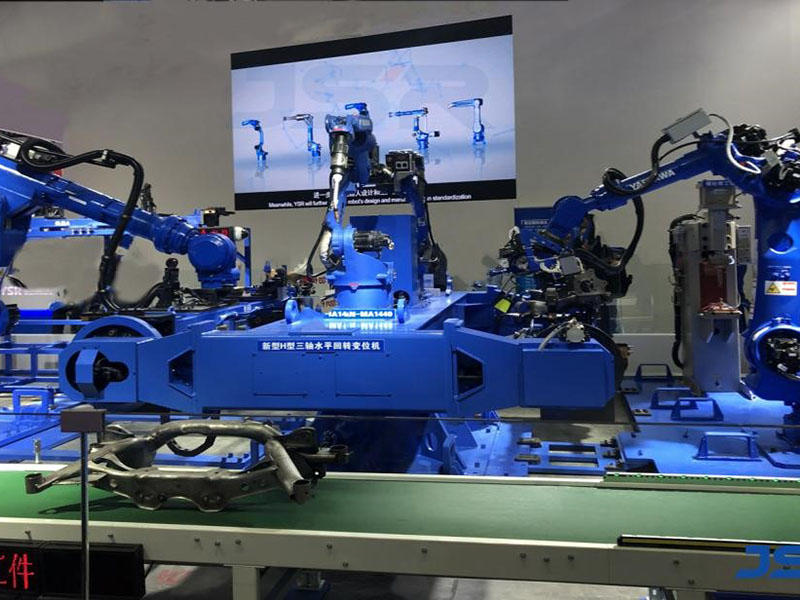

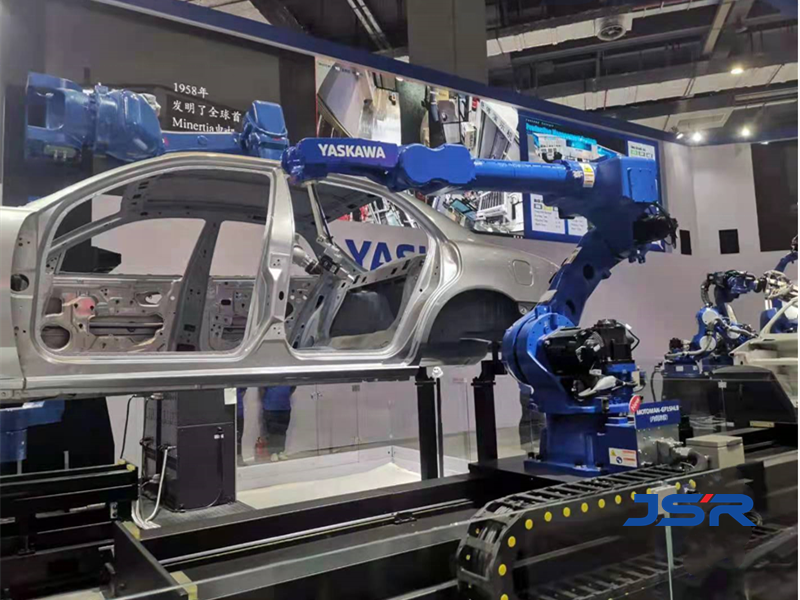

● Product applications

● Packing & Delivery