In recent years, medical automatic testing equipment has been favored due to its many advantages compared with manual operation, especially with the outbreak of the new crown epidemic, the demand for medical automatic testing equipment represented by nucleic acid testing and blood testing has surged since 2020. , reaching a compound annual growth rate of 45.8%.

In the process of medical biological testing, the opening, shifting, and label scanning of test tubes have always been the most routine and necessary operations. In the previous automated testing equipment, the operation of gripping and rotating the test tube was often realized by a gripper with a single gripping function and a series of peripheral rotating mechanisms, which took up a lot of space and was inconvenient to use and control. The compatibility problem and the problem of opening torque coverage are outstanding, which are widely criticized by users.

Chengzhou Robot aims at the pain point of this industry. At the end of 2020, it will launch an electric gripper (ERG series) that integrates gripping and rotating functions. The CEO of chegnzhou TC said: “This product is ready to meet user needs quickly and accurately. It is popular, and the monthly order has exceeded 1,000 units, making it a phenomenal star product in this segment.”

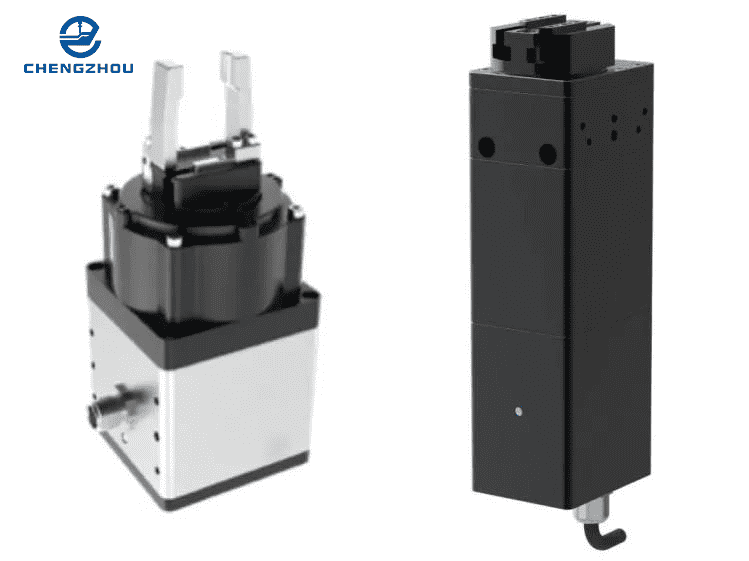

Chengzhou Electric Rotary Gripper ERG32-150

So, what exactly did Chengzhou ERG series rotary electric gripper do to get frequent orders?

1. Fully demonstrate a variety of technical routes

As early as mid-2019, Chengzhou Machinery Technology has started research on rotary electric grippers, and has tried to verify multiple possible technical routes.

Initially, Chengzhou Technology adopted the clamping and rotation as two coaxial rotations that can rotate relative to each other, which can save the slip ring. However, there is an insurmountable problem in this solution—that is, the rotation and the gripping action cannot be completely decoupled, that is, the rotational degree of freedom will shake during the gripping action, and the gripping will produce a certain range of inward gripping or The outward opening action has poor operation accuracy.

Chengzhou Technology comprehensively balances the practical performance of the product and the technical maturity of the core components, chooses the complete decoupling scheme, and customizes a special slip ring with long life to solve the connection and transformation between the clamping motor and the drive control board, making the product Function, performance and reliability can be guaranteed. Compared with the coupling scheme that was tried at the beginning, it has a greater cost advantage due to the saving of precision transmission components.

Chengzhou Technology’s two generations of ERG rotary electric gripper products

(The picture on the left is the first generation, the picture on the right is the second generation)

2. Seven technical details

◆ One machine can be compatible with more than 80% kinds of test tube opening operations

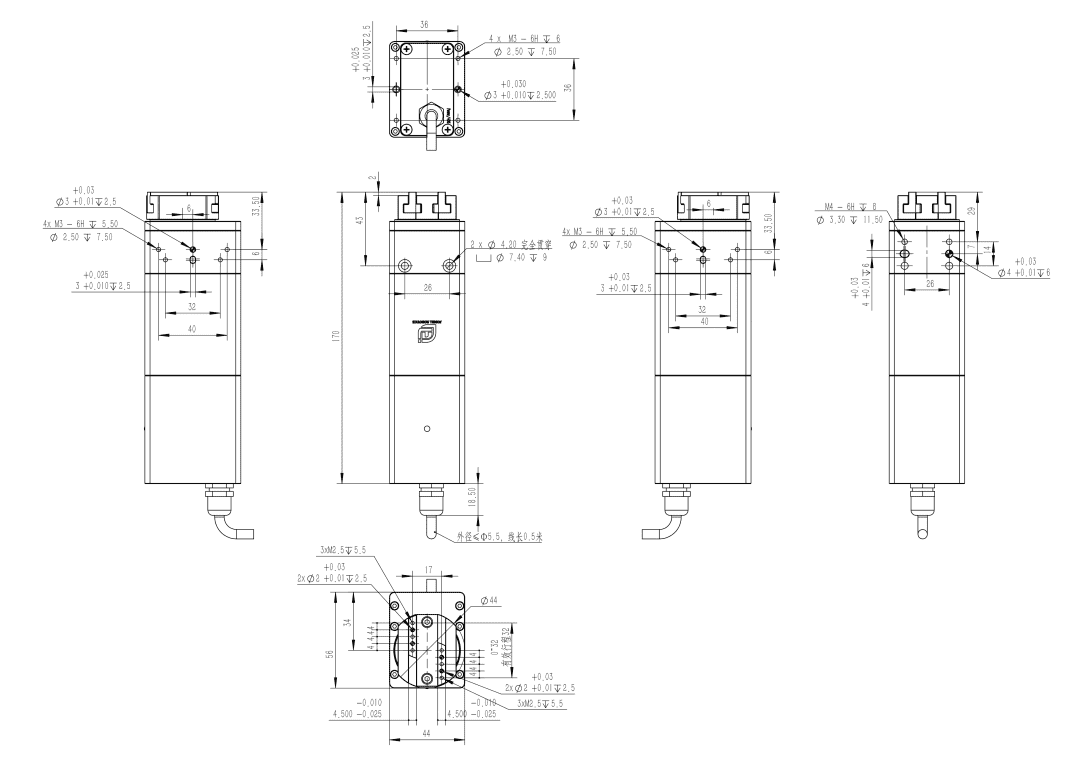

Chengzhou’s ERG32-150 rotary electric gripper has an adjustable gripper stroke of 32mm, a maximum gripping force of 150N, and a maximum rotational torque of 1Nm. % or more test tubes with different diameters and materials to ensure the opening rate.

◆ The waist shape of the product is only “44mm”, and the width size is unique

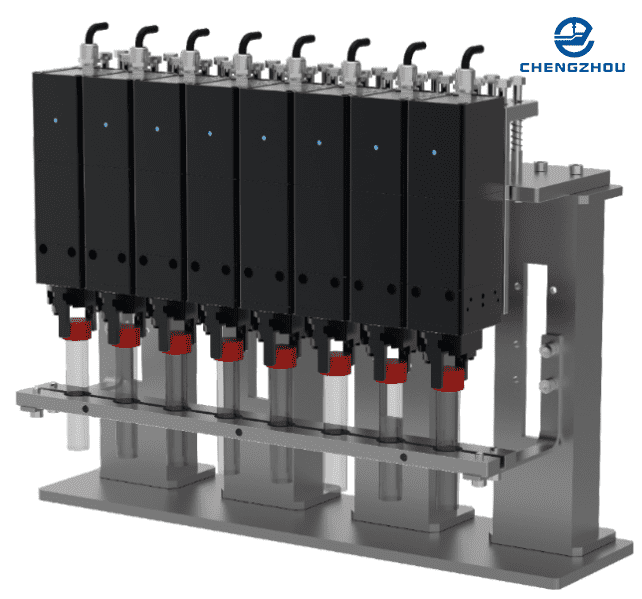

With the trend of increasing integration and automation efficiency, equipment space is at a premium. In medical automation equipment, the demand for matrix multi-target clamping operations is prominent. ERG32-150 has insight into this subtle rule of application scenarios. The width of the card position product is “44mm”, which can maximize its volume advantage

◆ Internally integrated EtherCAT and Modbus RTU bus

Chengzhou Technology is the first to launch a rotary electric gripper that is internally compatible with EtherCAT and Modbus RTU bus. EtherCAT is optional. It is very suitable for medical equipment with higher requirements for information transmission, and it truly means internal integration, and no additional communication configuration is required. conversion module.

◆ Standard T-shaped guide rails can ensure millions of grabs

The rotary electric gripper is equipped with Chengzhou T-type guide rail as standard, and the guide rail seat adopts the high-mature aluminum alloy hard coating process, which can ensure high positioning accuracy and at the same time, the performance of ten million times of grasping will not be degraded.

◆ The jaw head is the smallest replaceable unit for easy upgrades

Chengzhou’s rotary electric gripper ERG32-150 front hand parts and fingers can be customized and matched according to user needs, which greatly increases its application adaptability.

◆ It can be installed on 4 sides, providing users with more choices

The product fully considers the convenience of user installation, and is designed to have 4 optional installations, you can choose to install on the side of the proximal end of the clamping position, or you can choose to install it on the bottom surface of the far end of the clamping position.

◆ The control cable outlet is carefully designed, which is convenient for on-site wiring and disassembly

The product cable is divided into the electric claw end and the moving end. Chengzhou Technology abandons the aerial plug with large space requirements. The electric claw comes with a 0.5m cable to save space as much as possible at the outlet of the electric claw. At the same time, users can choose 3 meters and 5 meters. The sports cable and the electric claw end 0.5 cable are connected by plug and play, which greatly improves the convenience of application.

3. Work with customers to polish the control software

Today, Chengzhou’s rotary electric gripper has been tested by customers for half a year. Many functions and use designs are constantly polished with customers in a long-term joint test, and constantly accurately match the use requirements of the industry, and finally formed a A stable, reliable, easy-to-use software system.

Fourth, the technical service team has experienced “hard battles” for a long time

Chengzhou Technology has always had a team atmosphere of “guaranteeing the completion of tasks without making excuses”. For technical services and customer needs, we can always respond to support in the first time, and we can provide support through online video when customers request.

In addition to ERG32-150, Chengzhou also launched ERG26-015 high-integration-density rotary electric gripper with an outer diameter of only 35mm, which is currently a very small rotary and gripping integrated electric gripper. Adapt to the minimum 36mm test tube spacing.

Chengzhou Electric Rotary Gripper ERG26-015

At present, Chengzhou has developed 6 series of more than a dozen products, and the product applications have covered hundreds of customers in the medical, education, lithium battery, new retail, 3C, food packaging and other industries. , Chengzhou Technology has a monthly production capacity of 10,000 units.

Post time: May-31-2022