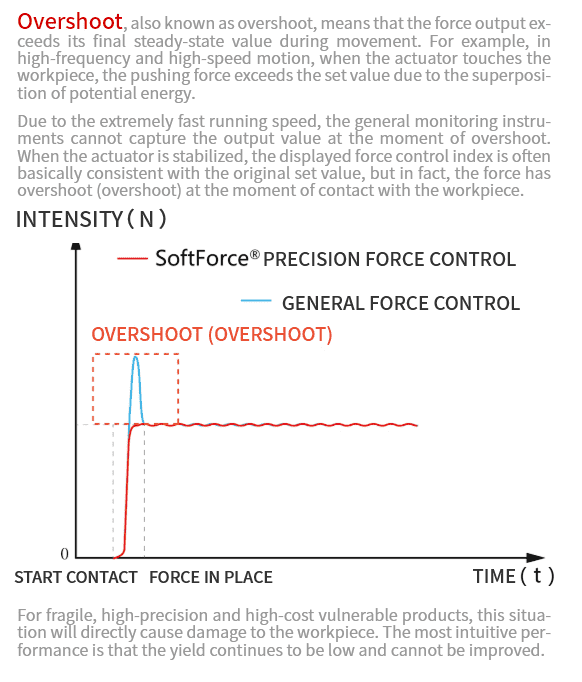

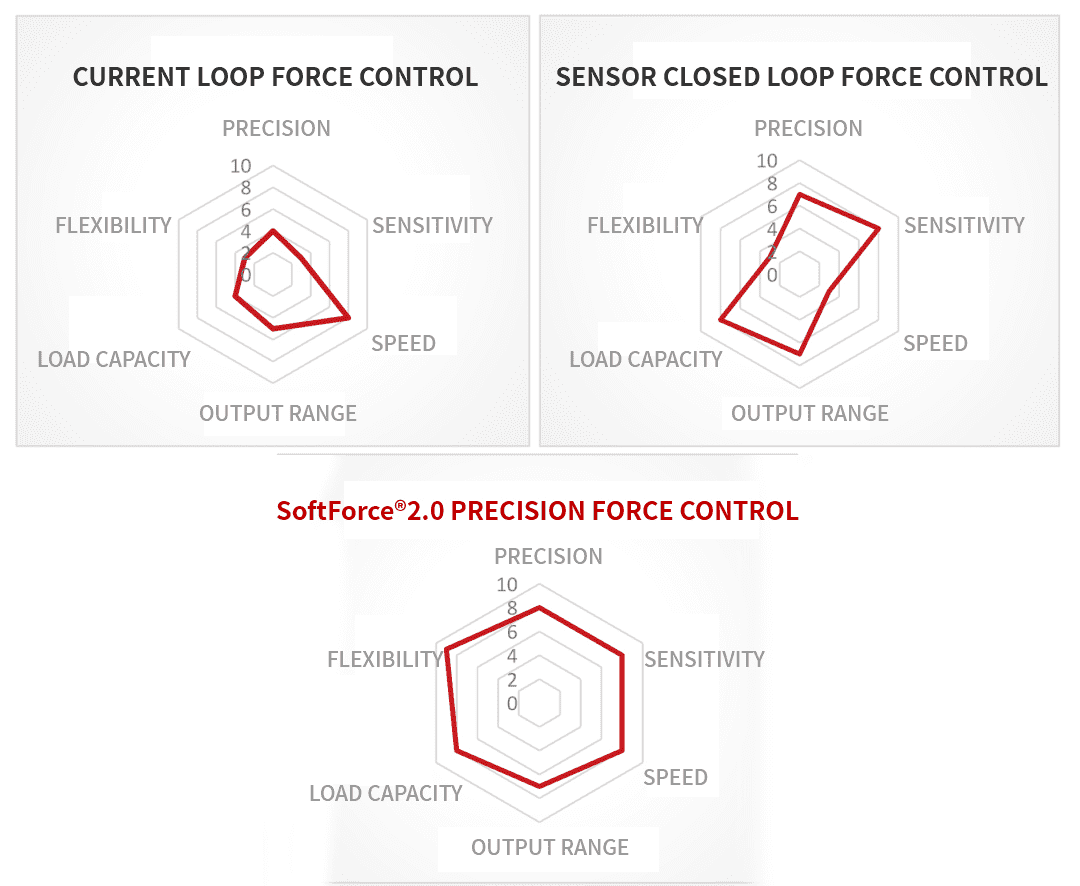

At present, most of the actuators on the market have two types of force control methods:

1. Current loop force control

A relatively easy to implement conventional force control method, which realizes force control by adjusting the internal current of the motor. The advantage is that it is less difficult to implement, and it can achieve force control within the range of 5%-15% accuracy; the disadvantage is that the movement speed is slow, it cannot be reversely driven, and it cannot meet the needs of some scenarios with higher precision requirements. After a period of use, mechanical wear will bring errors and further reduce the accuracy.

Such actuators usually do not have sensors, and even if there are sensors, they are only used as “displays” of force and do not participate in control. For example, adding a sensor to the press, the sensor reads the size of the force, and displays the value through the meter, which is used to assist the manual adjustment of the size of the force, but such adjustment generally has nothing to do with the accuracy of the force.

Schematic diagram, not related to graphics and text

2. Sensor closed-loop force control

Another force control method is to add a conventional force sensor and a conventional closed-loop control algorithm. The advantage is that the accuracy is improved, but the disadvantage is that the speed is still slow. In this way, the force control accuracy can be increased from 5% to 1%. If there is no correct algorithm processing, or the sensor speed is not fast enough, it is prone to “overshoot”.

Force Controlled Actuator

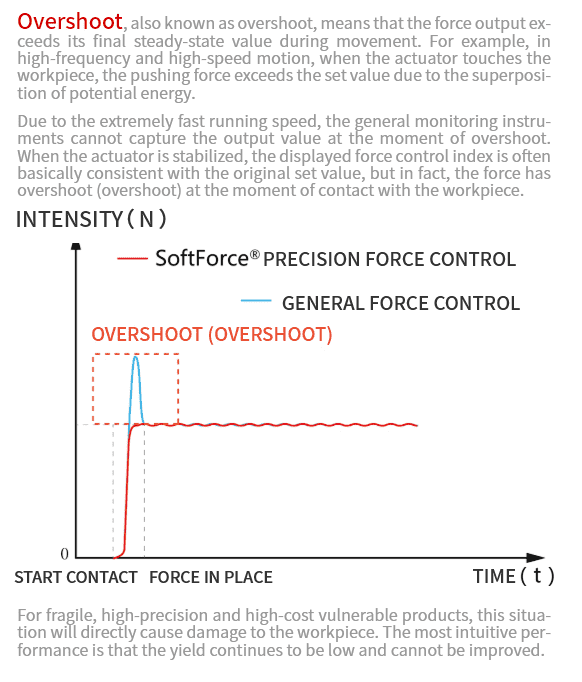

The inevitable “overshoot”?

The closed-loop force control method of the sensor is difficult to deal with the impact force. The most direct manifestation is that “overshoot” is very easy to occur when dealing with scenes with high tempo requirements.

for example

Generally, in the case of high speed and large output, the moment when the actuator contacts the workpiece is often particularly large. For example, if the pushing force of the actuator is set to 10N, it is easy to reach 11N and 12N when it touches the workpiece, and then it is called back to 10N through the control algorithm. Such problems often occur when force sensors and so-called force-controlled actuators are added to the market.

This is the problem that the response speed is not fast enough. High speed and precise and stable output are a pair of contradictions in themselves. If there is an overshoot (overshoot), the exact force in place is meaningless.

Especially in the precision equipment process of pressure assembly, fragile and high-cost parts, overshoot is generally not allowed.

Full force control, high frequency and high speed without overshoot?

How does TA do it?

For high-precision application scenarios, the “soft landing” method is adopted to take into account the requirements of high speed and high precision, that is, segmented force control. The actuator quickly approaches the workpiece through the position motion mode, quickly switches to the force control mode at the position where it is about to contact the workpiece, and gradually increases the output until it reaches the preset value. Position mode + force control mode + force stabilization time, the total time used is the single execution efficiency of the actuator.

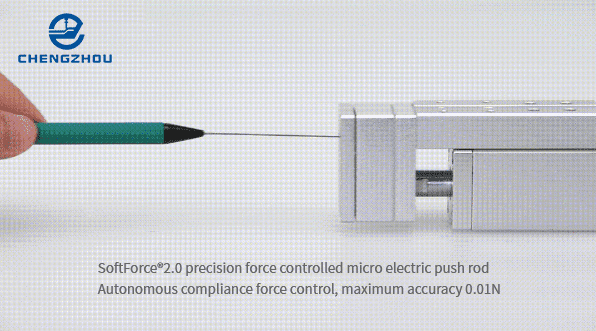

Combined with high-speed force sensor and model-based predictive control algorithm, SoftForce®2.0 precision force-controlled actuator can automatically identify the position of the actuator and the contact state with the workpiece, so that the actuator, as the end of the automation equipment, has the same function as a human hand. tactile perception, control and execution intelligence.

At the same distance, the soft landing speed range of “SoftForce ®2.0 Precision Force Control” is increased, the tolerance is larger, and it can even achieve full force control, which directly improves the production cycle and greatly reduces the cost of trial and error verification.

▋High processing frequency to achieve better performance

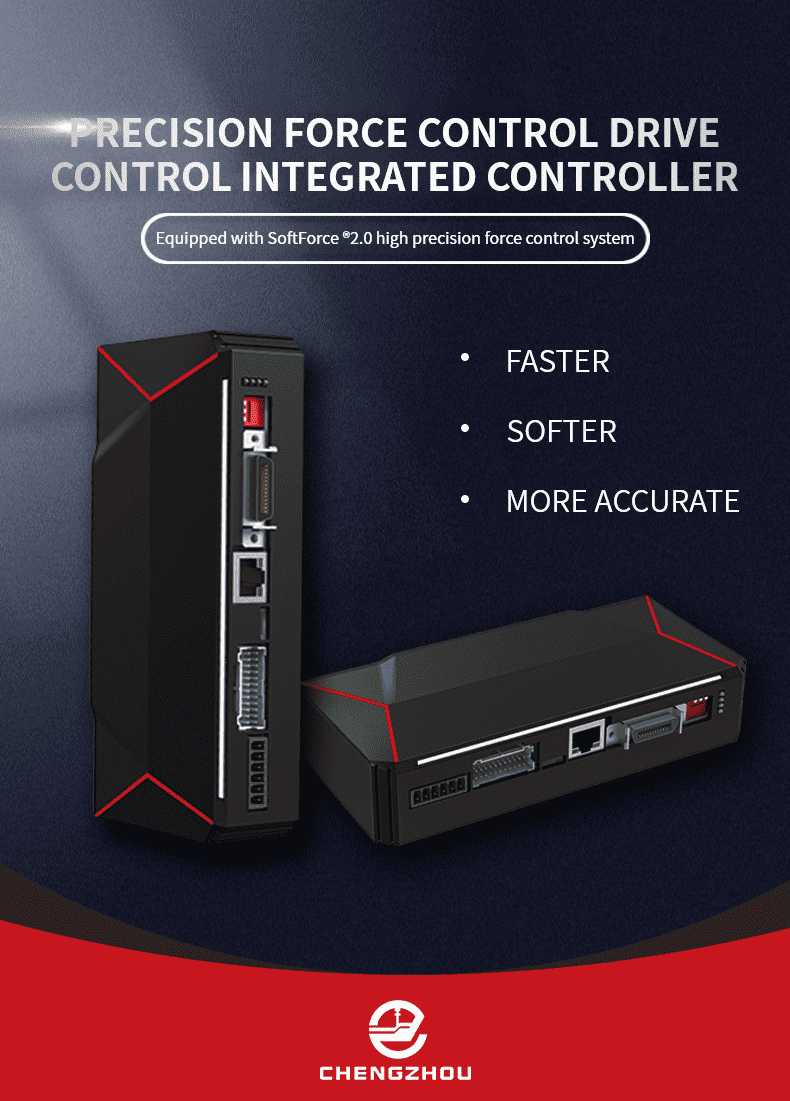

The calculation cycle of the “six-axis force sensor + robot” force control scheme commonly used in the market is 5-10 milliseconds, that is, the processing frequency is 100-200 Hz. The processing frequency of SoftForce®2.0 precision force-controlled actuators can reach 4000Hz (ie 0.25 milliseconds), and the high-frequency series models can reach 8000Hz, which is 4-8 times the processing frequency of general robot force-controlled actuators.

▋Active compliant force control, which can follow the change of external force

Efficient response rate and instantaneous force feedback enable the actuator to respond instantaneously to external forces and achieve active compliant force control. Even if external forces are encountered during operation, it can be adjusted in time, making the process more precise. Better protection of workpieces.

High frequency and high speed without overshoot

Even under high-frequency and high-speed motion, it still maintains high output accuracy, and at the same time ensures “soft landing” and “no overshoot”, contacts the surface of parts with high-speed, small force, and performs flexible picking and placement of parts, etc., to avoid damage to delicate and fragile parts. Components.

SoftForce®2.0 Precision Force Control

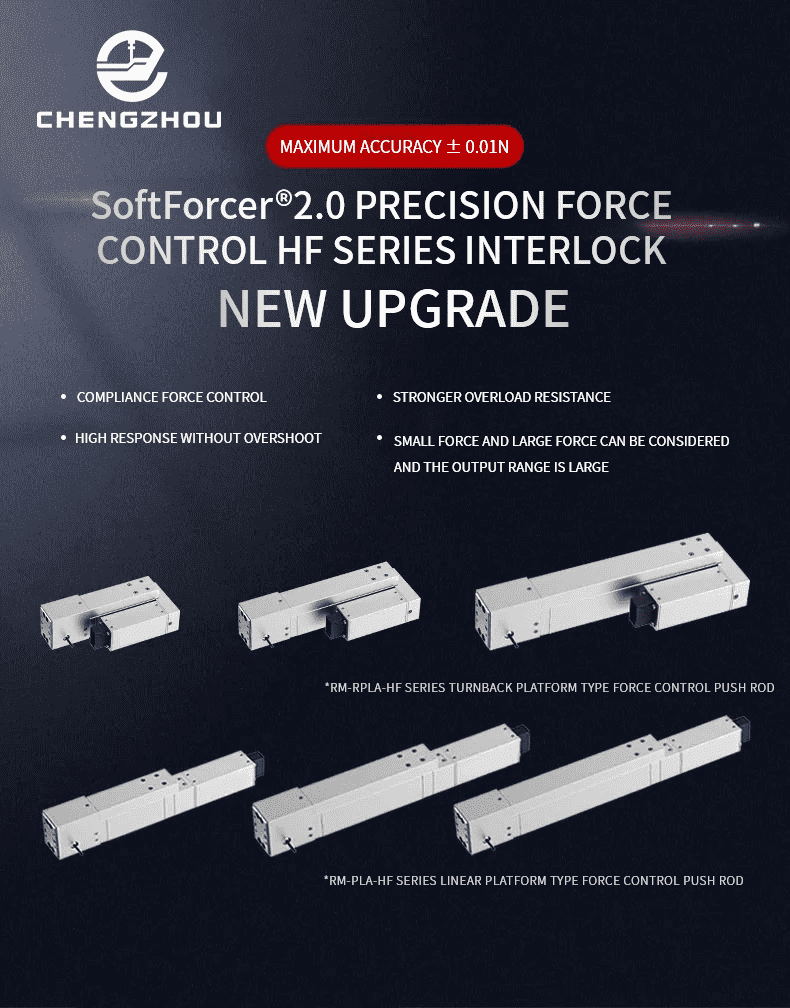

HF series new upgrade

▋ Stronger anti-overload capability

Based on the in-depth understanding of the on-site process and multiple iterations, Chengzhou’s newly upgraded SoftForce®2.0 precision force control HF series in February this year has an integrated sensor design, and its anti-overload capability is several times higher than in the past, with higher durability and ease of use. Cope with more complex conditions.

▋Can take into account both small force and large output

Equipped with the SoftForce®2.0 high-precision force control system, the precision force-controlled slide table and push rod with large stroke and large load can generate small and precise force under high load, and can also take into account the force at the same time, and the output range is wider. Larger, i.e. a wider force dynamic range*.

*Force Dynamic Range: The ratio between the maximum and minimum force that can be output.

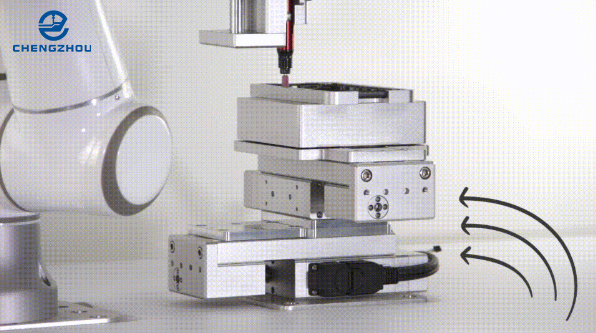

Precision force control can only be used on a single axis

SoftForce®2.0 precision force-controlled actuators can not only be used in a single axis, but also provide more possibilities for multi-axis assembly solutions. For example, the latest “RM Chengzhou 2D Synchronous Precision Force Control Platform Control System” launched by Chengzhou Technology is composed of two Chengzhou precision force-controlled electric actuators, which can replace the force of “six-axis sensor + robot” Control scheme, used for precision grinding and deburring of the inner frame of mobile phones, etc.

Chengzhou 2D synchronous precision force control platform control system

(Equipped with SoftForce®2.0 high-precision force control system)

Sophisticated and easy-to-use professional services

Advanced control algorithm and simple debugging process bring convenient user experience to customers. Even an operator with a low-level background can get started in 5 minutes, truly “plug and play”.

At the same time, Chengzhou Technology’s professional and strong after-sales technical service team can provide customers with timely, comprehensive and worry-free technical support in the first time, whether it is technical doubts, teaching, troubleshooting or maintenance.

Chengzhou Technology has always been brave enough to broaden its boundaries. With its solid and innovative technical strength, it has continuously launched more intelligent, more precise and more compatible high-quality actuator products to provide advanced products for semiconductor packaging and testing, 3C automation, precision manufacturing, smart medical and other industries. core components such as precision motion control systems and actuators.

Post time: May-31-2022