The following is a platform to teach you how to choose a suitable electric gripper!

[Q] How to quickly choose a suitable electric gripper?

[Answer] Quick selection can be made through five conditions:

① Select the clamping force according to the weight of the workpiece;

② Select the clamping stroke according to the size of the workpiece;

③ Select the suitable electric gripper and size according to the usage scenario;

④ Select functional items according to the grabbing requirements (such as power-off self-locking, envelope adaptation, infinite rotation, etc.),

⑤ Select an electric gripper that matches the IP level according to the requirements of the use environment.

[Q] What is an effective itinerary?

[Answer] It is the maximum range where the fingertips of the gripper can move freely. When the stroke of the gripper jaw is greater than the maximum distance required to move the fingertip, the gripper with that stroke is suitable.

[Q] Does the electric gripper support inner diameter clamping?

[Answer] The electric gripper supports internal diameter clamping, that is, the electric gripper can perform force control and speed control for both opening and closing.

[Q] What is the rotation angle supported by the rotary gripper?

[Answer] Rotating electric gripper RGI series supports infinite rotation.

[Q] What kind of motor is used for the electric gripper?

[Answer] Use high energy density permanent magnet synchronous DC motor. It adopts a high-efficiency slotless design. Compared with stepping motors and ordinary servo motors, it has high continuous torque, high efficiency, precise speed regulation, small size, light weight, low friction loss, and good dynamic acceleration and deceleration performance. Advantage.

[Q] How accurate is the electric gripper?

[Answer] The repeatability of the clamping position can reach up to plus or minus 0.02mm (two wires); the position separation rate can reach plus or minus 0.03mm (three wires); the force control accuracy can reach up to 0.1N (passed by the global manufacturing industry mass production verification of Top10 customers).

[Q] Compared with air claws, what are the advantages of electric claws?

[Answer] ① Electric grippers can achieve precise force control, and those that have requirements for gripping force control, such as thin and fragile components, will not cause damage to the components;

②The electric gripper can elastically adjust the clamping stroke to realize the clamping of components of different sizes;

③The clamping speed of the electric gripper is controllable, which can be intelligently planned to improve work efficiency;

④The drive-control integrated design of the electric gripper, directly connected to the bus, greatly simplifies the wiring of the production line and saves a lot of space, and is clean and safe;

⑤ The energy consumption of the electric gripper is much lower than that of the air gripper.

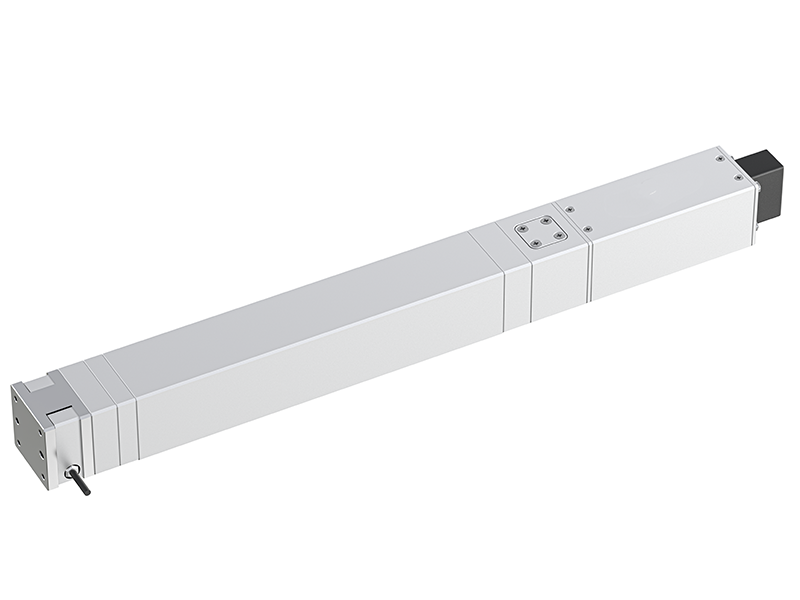

Small body, big energy electric actuator

1. Product introduction

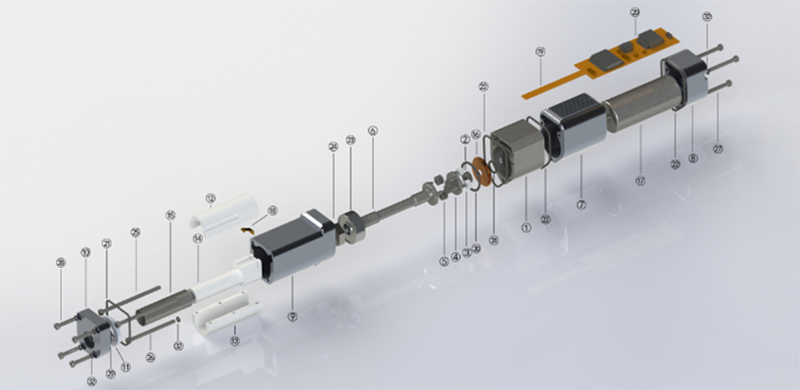

The miniature servo electric actuator integrates a micromotor, a planetary reducer, a screw mechanism, a sensor, and a drive and control system, which can realize precise servo control at any position within the stroke range. Built-in absolute position sensor, the position information will not be lost after power failure, and no zeroing operation is required.

Micro linear actuator structure diagram

The integrated design of micro servo actuator drive and control, small size, high power density, high precision force feedback and high positioning accuracy.

2. Main advantages

①The miniature servo electric actuator with the highest power density in China.

②The highest repeat positioning accuracy can reach micron level.

③ High level of integration, application engineers can focus on the development of equipment functions.

④It has rich mechanical interface and electrical interface.

⑤More than 100 models meet the needs of various application fields.

⑥Localized production, stable delivery period, support special customization.

3. Product application direction

Main applications: medical industry, scientific research and education, industrial automation, aerospace, consumer electronics.

4. What is the working principle of the linear actuator?

Micro Linear Actuator is a micro servo electric push rod, which integrates micro motor, reducer, screw mechanism, sensor and drive control system, and can realize precise servo control at any position within the stroke range. Built-in absolute position sensor, the position information will not be lost after power failure, and no zeroing operation is required.

5. Which series can be divided into according to the function?

Miniature linear servo drives can be divided into two series: standard type and force control type according to their functions. The corresponding signal acquisition and filtering algorithm can detect the actual force of the micro linear servo drive

Post time: Feb-04-2023