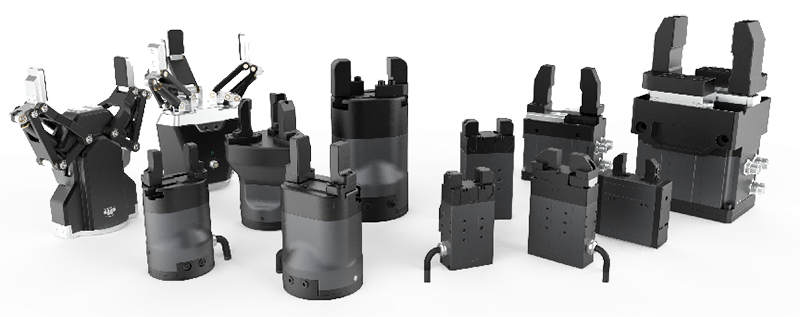

The electric gripper series products are products with a high degree of precision. This article will introduce the mechanical principle, product characteristics, and specific applications of the electric gripper. I hope readers can initially establish knowledge about electric gripper products. basic impressions and perceptions.

1. Mechanical principle of electric gripper

To put it simply, the mechanical principle of the electric gripper is actually the function of two pistons. Each piston is connected to the pneumatic finger via a roller and a hyperbolic pin, thus forming a special drive unit. In this way, the pneumatic fingers can always move axially towards the center, but each finger cannot move independently. If the pneumatic finger moves in the opposite direction, the previously compressed piston will be exhausted and the other piston will be compressed.

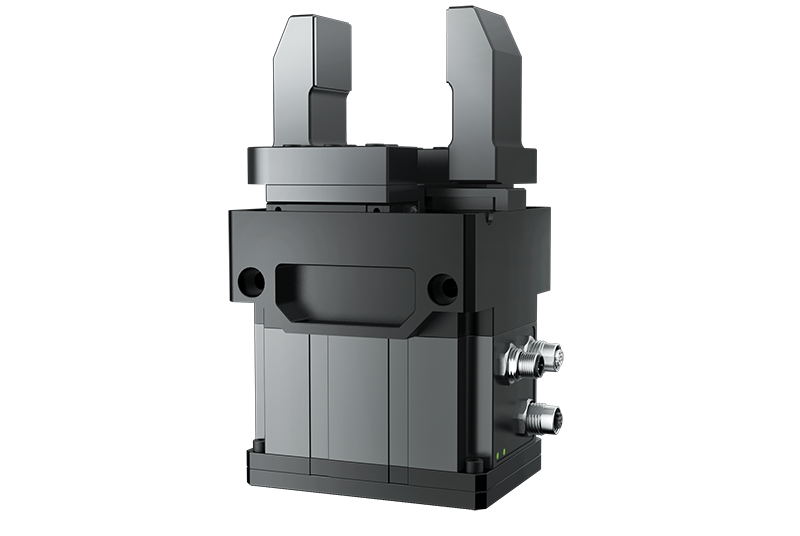

The parallel jaws of the electric gripper are driven by a single piston, whose crank is driven by the shaft itself. The two jaws each have an opposing crank slot. In order to further reduce frictional resistance, the claw and the body also adopt a connection structure of steel ball slide rails.

2. Product features of electric gripper

1) The body of the electric gripper has a built-in motor, which is an intelligent product integrating drive and communication functions. Moreover, the overall volume of the electric gripper is small, which is also more convenient for users to install and use.

2) The electric gripper has a strong rotation function and clamping function, and the rotating double jaw can realize the rotation function and the clamping function at the same time.

3) The electric gripper has the ability of high-precision positioning and voltage protection. It is manifested in that the electric gripper can not only locate the real-time position of rotation and clamping with high precision, but also has various protection functions such as overvoltage, overcurrent, stalled rotor and overheating for the supply voltage during its working process.

4) The speed and current of the electric gripper can be adjusted at any time during operation, and the adjustment will take effect in time. Equipped with dual NPN opto-isolated inputs to control the forward and reverse rotation of the motor.

3. Advantages of electric gripper

1) The electric gripper can achieve accurate force control. Therefore, electric grippers are very suitable for some scenes with strict requirements for gripping force control, such as when using electric grippers to grip thin and fragile components, it will not cause damage to the components.

2) The electric gripper can elastically adjust the gripping stroke, so as to realize the gripping process of components of different sizes.

3) The clamping speed of the electric gripper can also be flexibly controlled. In the process, intelligent planning and program control can be used to accurately and quickly complete the processing tasks required by the formulation of the program and improve the working efficiency of the gripper.

4) The integrated drive and control design of the electric gripper greatly simplifies the wiring of the production line, saves a lot of space and ensures the safety and cleanliness of the environment.

4. Practical application of electric gripper

1) Workpiece identification

The scene where the electric gripper is used for workpiece identification is mainly to use the clamping type to insert the workpiece for tolerance judgment. It is mainly to prevent the mixing of workpieces with different diameters or the outflow of substandard products.

2) Workpiece press-in

The combined movement of the electric gripper combined with the push rod to press into the workpiece can use the judgment function to detect the error of “whether a defective product is pressed” or “whether the workpiece is chucked”. Typical scenarios include terminal press-fitting of small parts, riveting of housings, and so on.

3) Clamping of fragile items

The clamping force, speed, and stroke of the electric gripper can be flexibly adjusted, so it can be applied to the clamping of vulnerable items such as test tubes, eggs, and egg rolls.

4) Inner diameter measurement

The clamping mode of the electric gripper can be used to judge the tolerance of the inner diameter of the workpiece.

Post time: Dec-12-2022