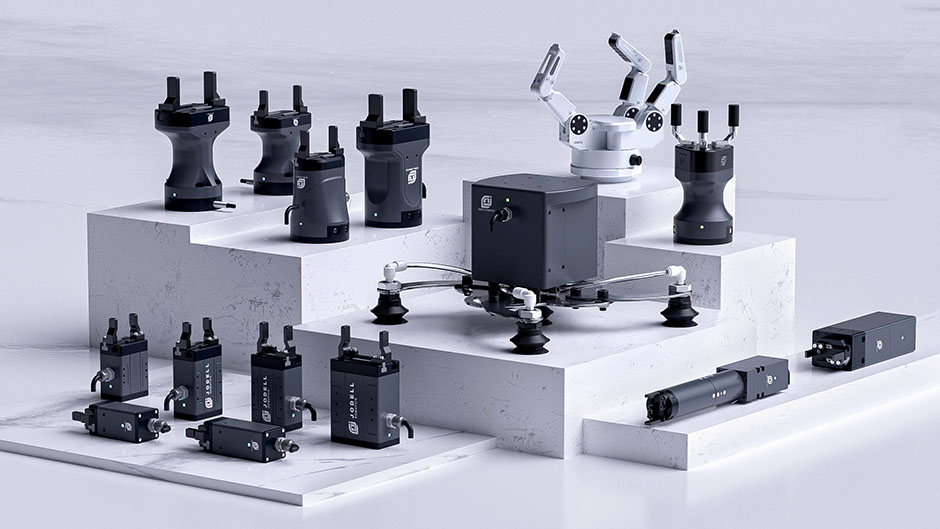

Electric gripper: applied in the field of industrial automation, in simple terms, it is a gripper made by a robot imitating our human hands. Now there are more and more robots around us, have you ever had an in-depth understanding of their claws? Take you to an in-depth understanding of the electric gripper.

The opening and closing of the gripper has the function of programmable control to realize multi-point positioning. The pneumatic gripper has only two stop points, and the electric gripper can have more than 256 stop points; the acceleration and deceleration of the electric finger is controllable, and the workpiece The impact can be minimized, and the gripping of the pneumatic gripper is an impact process. The impact exists in principle and is difficult to eliminate. The clamping force of the electric gripper can be adjusted, and the closed-loop control of the force can be realized. The power and speed are basically uncontrollable and cannot be used in highly flexible and delicate work situations. On the one hand, the incremental market represented by collaborative robots continues to increase volume, which will form a strong demand pull for electric grippers; on the other hand, in the stock market represented by industrial automation, many scenarios gradually derive electric grippers instead of pneumatics New opportunities for grippers.

On the one hand, the incremental market represented by collaborative robots continues to increase volume, which will form a strong demand pull for electric grippers; on the other hand, in the stock market represented by industrial automation, many scenarios gradually derive electric grippers instead of pneumatics new opportunities for grippers.

Electric grippers can be seen everywhere in the factory, but insiders know that only the electric gripper itself cannot work, and it needs the support of the air source and the auxiliary system. As an executive component, the support system of the electric gripper is particularly complex, including a series of high-pressure air sources, pneumatic triples, pipelines, pipeline joints, throttle valves, silencers, magnetic switches, middle-sealed solenoid valves, and pressure switches. Pneumatic components.

Electric gripper: used in the field of industrial automation, compared with pneumatic fingers, it has the following characteristics: some models have a self-locking mechanism to prevent damage to workpieces and equipment caused by power failure, which is safer than pneumatic fingers; the opening and closing of the gripper has programmable control The function of multi-point positioning, the pneumatic gripper has only two stop points, and the electric gripper can have more than 256 stop points; the acceleration and deceleration of the electric finger can be controlled, and the impact on the workpiece can be minimized, while the pneumatic gripper can have more than 256 stop points. The clamping of the jaws is an impact process, and the impact exists in principle and is difficult to eliminate; the clamping force of the electric clamping jaws can be adjusted, and the closed-loop control of the force can be realized. The accuracy of the clamping force can reach 0.01N, and the measurement accuracy can reach 0.005mm (currently, only Dongju can do it), the power and speed of the pneumatic gripper are basically uncontrollable, and cannot be used in highly flexibl,The electric gripper is the end clamping device of the mechanical arm. During the whole process of using the electric gripper, multiple grippers can accurately synchronize their actions, and stabilize and accurately clamp and place the product. The fixture has zero contact with the surface of the product to achieve the effect of traceless handling.

Post time: Apr-25-2022